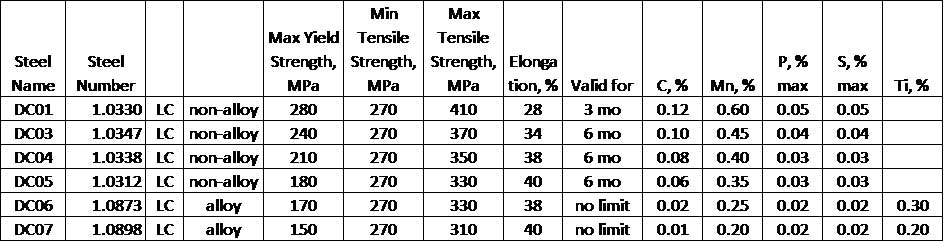

Commercial steel forming steel deep drawing steel extra deep drawing steel structural steel high strength low alloy steel high strength low alloy steel with improved formability solution hardened steel and bake hardenable steel.

Galvanized of batch annealed steel sheet.

Galvanized steel is less conducive to forming welding and painting.

Annealing recrystallizes the grain structure restoring ductility so the material can adequately.

Continuous sheet galvanizing is also a hot dip process but is only applied to steel sheet strip and wire.

A coil to coil process steel sheets from 0 010 to 1 70 inches 0 25 mm to 4 30 mm thick and up to 72 inches 1 830 mm wide is passed as a continuous ribbon through cleaning baths and molten zinc at speeds up to 600 feet per minute.

Galvannealed steel is the preferred coated steel for use in architectural applications.

While you can now make parts with thinner steels you have to be sure that they will not rust through.

Galva annealed steel sheet offers significant improvements in weldability and paintability by undergoing a simple pre treatment process.

Annealing of cold rolled steel involves a time and temperature controlled thermomechanical process used predominantly to make steel soft again after cold reduction.

Since then several improvements have been made in the process which allows several types of steels to be processed by this method.

We will be glad to help you select the exact grade for your galvanized steel sheet coil.

Stelco s potential production of up to 200 000 net tons of fully processed annealed cold rolled steel sheet per year.

Galvanized galvannealed astm a 653 this specification covers steel sheet zinc coated galvanized or zinc iron alloy coated galvannealed by the hot dip process in coils and cut lengths.

The material is available in several designations as follows.

Specification astm a 653 a 653m coating designation a a60 a40 galvanized steel zinc coated by the hot dip process resulting in a full spangled finish.

Zinc coatings protect the steel by a chemical reaction.

Paint coatings provide a physical barrier to corrosion.

Cold reduction or work hardening makes steel grain structure small and elongated.

After the coating process a special heat treatment forms an alloy layer between the galvanized layer and the metal base.

This produces high strength but low elongation.

Forward looking information in this news release includes the potential for stelco to service new markets with the type of fully processed annealed cold rolled steel sheet that stelco expects to produce.

Batch hot dip galvanizing also known as general galvanizing produces a zinc coating by completely immersing the steel product in a bath kettle of molten zinc prior to immersion in the zinc bath the steel is chemically cleaned to remove all oils greases soil mill scale and oxides.

And the completion of.